Ho thatafala ha Induction KE ENG?

Ho thatafatsa ha Induction ke eng?

Ho thatafatsa induction ke mokhoa oa ho tima o sebelisang molao-motheo oa induction ea electromagnetic ho etsa hore sesebelisoa sa mosebetsi se khaole mehala ea matla a khoheli sebakeng se fapanyetsanang sa makenete mme se hlahise hona joale sebakeng sa likarolo tsa tšepe. Ho ea ka phello ea letlalo la alternating current, bokaholimo ba karolo e futhumetseng bo futhumetse ka potlako ka mokhoa oa eddy current ebe joale induction e tima ka potlako.

Ka mor'a hore mochini o futhumatsang e qeta mokhoa oa ho futhumatsa le ho tima, likarolo tsa tšepe holim'a boima bo phahameng, motheo o boloka polasetiki e ntle le ho tiea, o bonts'a kutloisiso e tlaase, kahoo matla a ts'ebetso, matla a mokhathala le ho hanyetsa ho roala li ntlafatsoa haholo. Ka lebaka la nako e khuts'oane ea ho futhumatsa, oxidation ea bokaholimo, le decarburization ea likarolo tse fokolang, ha li bapisoa le liphekolo tse ling tsa mocheso, sekhahla sa ho hana likarolo se tlase haholo. Hape ho khetha coil e loketseng ea ho futhumatsa ho kenya letsoho ho phetha karolo ea bohlokoa tšimong ea phekolo ea mocheso oa tšepe ea tšepe.

Hobaneng u sebelisa mokhoa oa ho thatafatsa induction?

Induction quenching ke ts'ebetso eo ho eona maqhubu a eddy a hlahisoang ka har'a tšepe ea tšepe ka induction ea electromagnetic mme sesebelisoa sa mosebetsi se futhumatsoa. Ha ho bapisoa le theknoloji e tloaelehileng ea ho futhumatsa tšepe, theknoloji ea quenching ea induction e na le melemo e latelang:

1. The metal workpiece holim'a thatathata e phahameng. Ho thatafala ha holim'a sesebelisoa se thatafalitsoeng ke mocheso o phahameng le o mahareng oa ho futhumatsa ke 2 ~ 3 HRC e phahameng ho feta ea ho tima ho tloaelehileng. Matla a eona a ts'ebetso ea tšepe, matla a mokhathala, le ho hanyetsa ho roala li ntlafatsoa haholo. Bophelo ba ts'ebeletso ea tšepe ea tšepe bo ka atolosoa haholo ka ho tima induction.

2. Sesebelisoa sa tšepe ha se futhumale ka mokhoa o ts'oanelang, ka hona ka ho thatafala ha induction, deformation ea workpiece ka kakaretso e nyane;

3. Nako ea ho futhumatsa ea tšepe ea tšepe e khuts'oane, bokaholimo ba oxidation decarburization bo fokotseha;

4. Mohloli oa ho futhumatsa o sebetsa ka holim'a tšepe ea tšepe, lebelo la ho futhumatsa le bokhoni bo phahameng;

5. Sebopeho sa lisebelisoa tsa ho tima li-induction se kopane ho feta lisebelisoa tse tloaelehileng tsa ho futhumatsa ka tšepe, ho bonolo ho li sebetsa.

6. Mochini o thatafatsang oa induction o hlokomela ts'ebetso ea mochini le othomathiki oa kalafo ea mocheso, o boloka litšenyehelo tsa basebetsi.

7. Theknoloji ea ho thatafatsa ka induction ho thatafatsa bokaholimo le eona e ka sebelisoa ho futhumatsang ho kenellang le kalafong ea mocheso oa lik'hemik'hale.

Mokhoa oa ho khetha mokhoa o nepahetseng oa ho thatafatsa induction?

Ts'ebetso ea ho thatafatsa ea induction e na le mekhoa e mengata ea ho futhumatsa mme kaofela e na le lisebelisoa tsa ho futhumatsa tse loketseng.

1. Mokhoa oa nako e le 'ngoe oa ho thatafatsa mocheso oa induction:

Ho futhumatsa ha nako e le 'ngoe kapa ho futhumatsa ka nako e le 'ngoe ke mokhoa o tloaelehileng oa ho thatafatsa oa induction. Ha mokhoa ona o sebelisa li-tubes tse peli tse khutlonnetsepa tse pota-potileng sebaka sa mosebetsi bakeng sa ho futhumatsa ka rotary, ka tloaelo o bitsoa Single Shot.

Monyetla oa mokhoa ona oa ho futhumatsa ka induction ke ho phethela mesebetsi eohle ea ho futhumatsa sebaka sa mosebetsi ka nako e le 'ngoe. Ka hona, ts'ebetso ea eona e bonolo, tlhahiso e phahame, e loketse ho futhumatsa sebaka sa workpiece ha se seholo haholo. Bakeng sa ho futhumatsa sebaka se seholo sa mosebetsi, sebelisa mokhoa oa ho futhumatsa ka nako e le 'ngoe, o hloka matla a mangata le litšenyehelo tse phahameng tsa matsete.

Mehlala e atileng haholo ea ho thatafatsa ho futhumatsa ha nako e le 'ngoe ke li-gear tse nyane le tse mahareng tsa modulus, likhetla tse bōpehileng joaloka tšepe ea CVJ, litselana tsa ka hare, mabili a tsamaisang, mabili a ts'ehetso, lithakhisa tsa makhasi, lithapo, li-valve, li-valve rocker arm arcs, jj.

2. Mokhoa oa ho thatafatsa oa induction:

Ha sebaka sa ho futhumatsa sa workpiece se le seholo, motlakase oa ho futhumatsa oa induction o monyenyane, mokhoa ona o atisa ho sebelisoa. Nakong ena, sebaka sa ho futhumatsa se baloang S se bolela sebaka se nang le lesale la induction. Ka hona, matla a matla a tšoanang, a mochini o futhumatsang matla a hlokahalang ke a manyane, tlholisano mochini o thata oa ho kenya litšenyehelo tsa matsete li tlase, li loketse tlhahiso e thata ea batch induction, mehlala e tloaelehileng ke molamu oa piston oa bophara bo boholo, mokoloto o entsoeng ka masenke, moqolo, lipeipi tsa oli, molamu oa sucker, seporo, seporo sa tataiso ea lisebelisoa tsa mochini joalo-joalo.

3. Karolo ea nako e le 'ngoe ea ho futhumatsa mocheso mokhoa oa ho tima

Mehlala e tlwaelehileng ke multiple camshafts induction thatafatsa, nako le nako ha mocheso e mong kapa ho feta cams, ka mor'a ho qeta nako ena induction quenching, futhumatsang karolo e 'ngoe cam, likere li thatafatsoa leino ka leino le ka kenyelletsoa sehlopheng sena.

4. Subsection induction scanning mokhoa oa ho tima

Mehlala e tloahelehileng ke li-valve rocker shafts kapa ho thatafala ha li-speed shafts induction, moo likarolo tse ngata tsa shaft li hlahlojoang bakeng sa ho tima, bophara ba ho tima bo ka fapana, 'me mokhoa oa ho tima meno ka leino o ka kenyelletsoa sehlopheng sena.

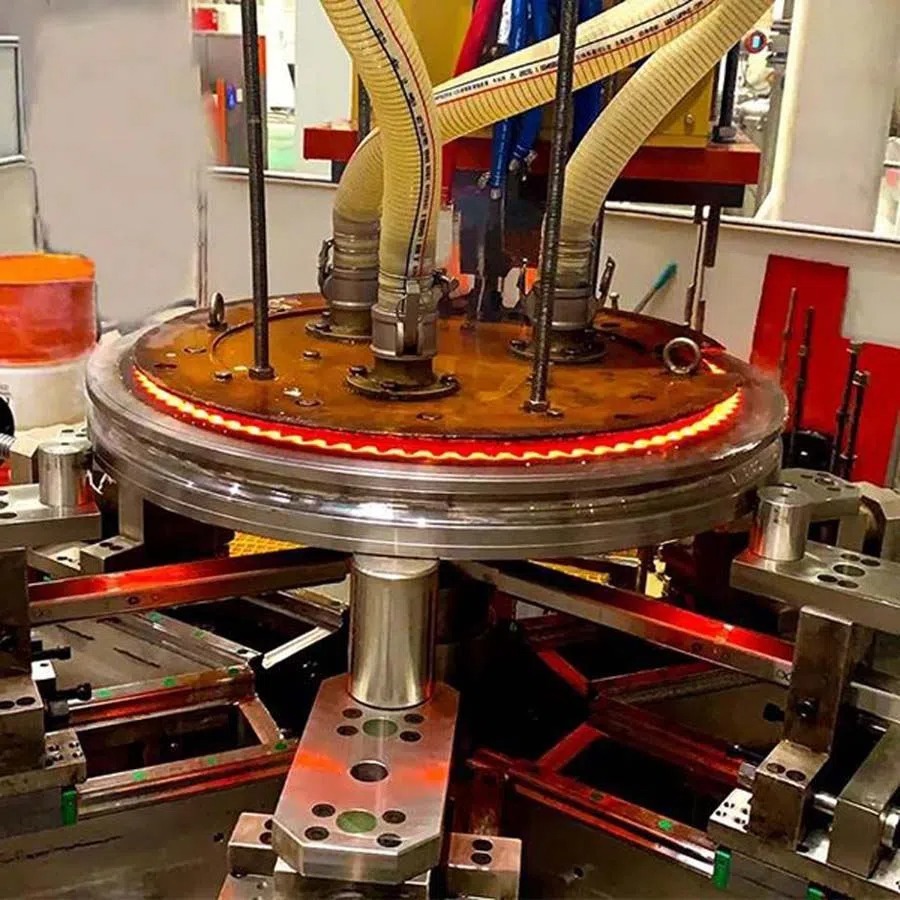

5. Ho futhumatsa le ho tima ka metsi

Induction thatafatsa quenching ka mokelikeli, ho bolela ho coil induction 'me sebaka sa ho futhumatsa sa workpiece se qoelisoa ka har'a mokelikeli o timang ka induction, o futhusitsoe, ka lebaka la matla a matla a ho futhumatsa holim'a metsi a mangata ho feta sekhahla sa ho pholisa sa mokelikeli o timang. Ka hona, bokaholimo bo chesa ka potlako. Ha inductor e felloa ke matla, karolo e ka holimo ea mosebetsi e thatafalloa ka lebaka la ho kenngoa ha mocheso oa motsoako oa mosebetsi le ho pholile ha metsi a timang.

Mokhoa ona ka kakaretso o loketse mosebetsi oa tšepe oa tšepe o hlokang tekanyo e fokolang ea ho pholisa. Ha workpiece e behoa moeeng 'me coil induction e tima, mocheso oa holim'a metsi o kenngoa ke setsi sa mosebetsi. Ha tekanyo ea pholileng ea sebaka se futhumetseng se le seholo ho feta tekanyo ea ho pholile ea bohlokoa, mosebetsi oa ho sebetsa o thatafalitsoe, o tšoanang le ho tima ka mokelikeli.

Likarolo tsa tsamaiso ea ho thatafatsa induction ke life?

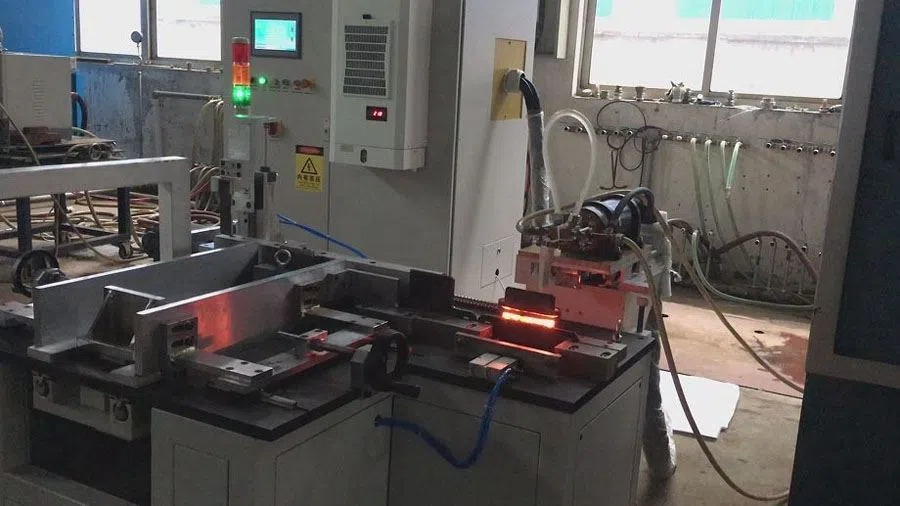

Sebopeho sa botlalo mochini o tima motlakase ka kakaretso e kenyelletsa phepelo ea motlakase ea ho futhumatsa, sesebelisoa sa mochini o thatafatsang oa CNC, coil e thatafatsang, le sistimi e thusang ea phepelo ea metsi a pholileng le mokhoa oa ho tima metsi.

Baetsi ba lisebelisoa tsa sejoale-joale tsa ho futhumatsa ka induction, karolo e kholo ea bokhoni ba ho etsa sete e felletseng ea lisebelisoa tse thatafatsang tsa induction le projeke ea turnkey, mosebelisi ho tloha molemong oa ho khutsufatsa potoloho ea tlhahiso, mme a qojoa ka lebaka la lefapha la phepelo e ngata nakong ea debugging ha e lumellane, le mathata a nako e telele a debug joalo ka nako. Phepelo ea lisebelisoa tse felletseng le merero ea turnkey e fetohile mokhoa oa tlholisano bakeng sa baetsi ba lisebelisoa.

Ka kakaretso, joalo ka e mong oa baetsi ba sistimi e thatafatsang ea induction naheng ea China, re thusitse lifeme tse likete tsa kalafo ea mocheso ho fumana litharollo tse nepahetseng tsa kalafo ea mocheso oa induction, ka hona, e le ho etsa bonnete ba hore ts'ebetso ea ho tima tsamaiso ea induction e loketse. Ke kopa o ntumelle hore ke be le likarolo tsa hau tse thata tsa litšoantšo, thepa, boima, le likopo tse tebileng tse thata, 'me re ka u fa litlhahiso tsa tekheniki tse amanang le ho futhumatsa tsamaiso ea mocheso hammoho le maqephe a quotation. Kea leboha.

Induction Hardening Quenching System Maemo a Kopo a Karolo

1. E sekametseng paatsepama peisong CNC induction quenching mochine tsamaiso

2. Sisteme ea ho thatafatsa ea Chain Plate Induction

3. Cantilever gear CNC induction thata tsamaiso ea mochine

4. Wind Power Bolt Induction Quenching le Tempering System Production Line

5. E leka-lekaneng shaft khetla ka hare ho lesoba ho futhumatsa tsamaiso thatafatsa

6. Large Mill Roller Induction Hardening